Precision Matters: How to Select the Right PT Electrode Tip Manufacturing Partner

In EP catheter manufacturing, electrode tip quality directly affects clinical outcomes. Discover how to choose a partner with the expertise to get it right.

The global electrophysiology catheter market – valued at $8 billion in 2024 – is growing rapidly. This expansion is being driven by a rising incidence of cardiac arrhythmias, a strong shift toward minimally invasive procedures, and groundbreaking advances such as 3D mapping systems and pulsed field ablation (PFA). As a result, demand for precision-engineered catheter components is higher than ever.

As this market grows, so does the pressure on OEMs to scale quickly and reliably. Electrode tips, particularly those made from platinum-iridium, are mission-critical components that must meet strict standards for signal clarity, surface finish, and biocompatibility, while also being manufacturable at scale.

The Role of Contract Manufacturing in Meeting Demand

For medical device companies navigating this evolving landscape, a strategic partnership with a skilled contract manufacturer has become even more important. The ability to deliver precision-machined components while adapting to shifting project scopes and quality demands is now a competitive necessity.

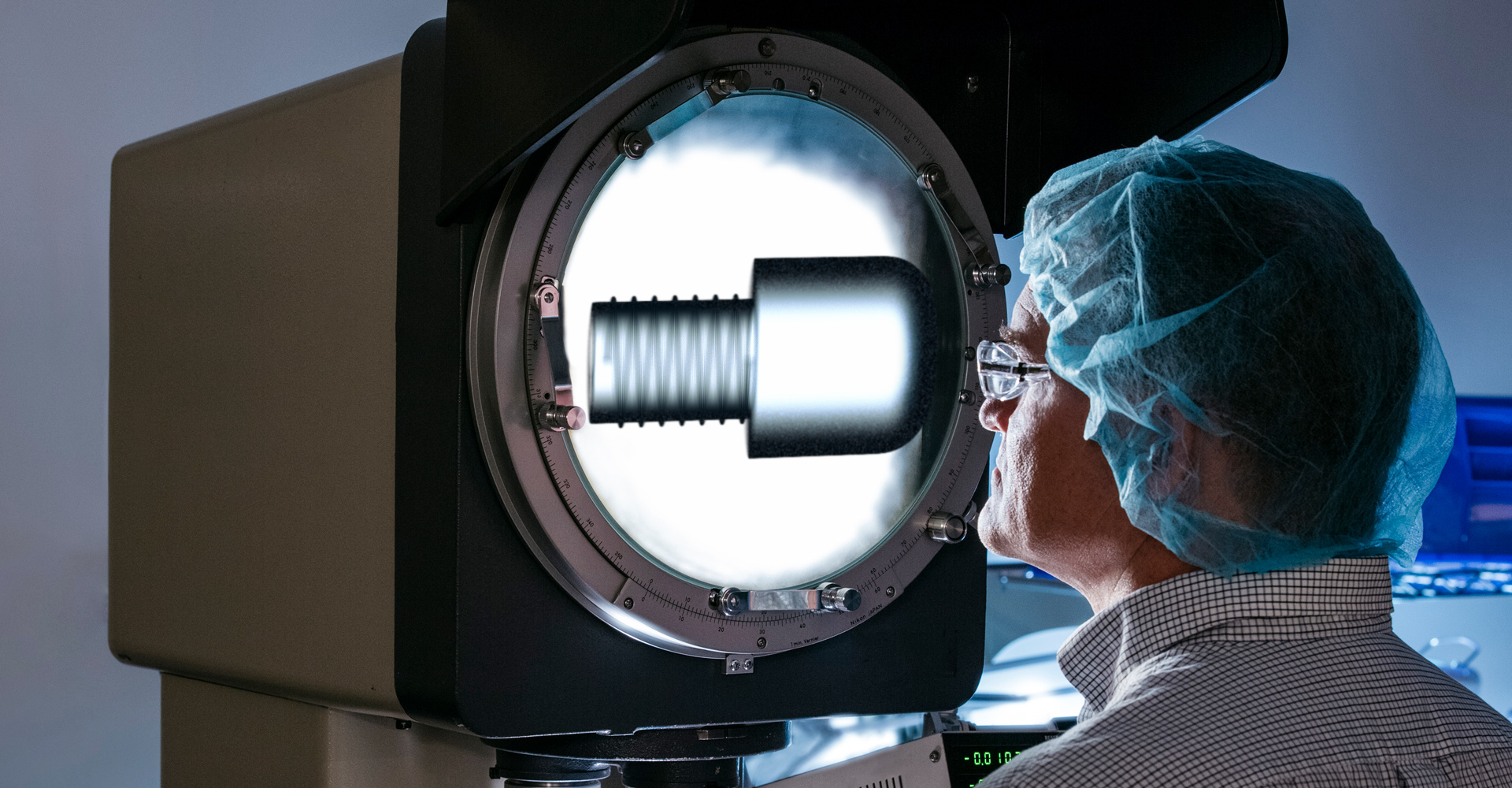

While manufacturing electrode tips comes with challenges – hard-to-machine materials, complex geometries, tight tolerances – solutions do exist. The most capable manufacturing partners combine engineering expertise with advanced tooling, DFM insight, and robust quality systems to deliver repeatable, compliant, and high-performing results.

Explore our white paper for guidance on:

- Why platinum-iridium electrode tips are preferred despite the challenges in machining them

- How manufacturing choices impact signal quality, safety, and clinical outcomes

- Regulatory and QA essentials: inspection methods, validation protocols, and risk management

- Advanced machining methods including CNC, EDM, and laser-based micro-manufacturing

- How the right manufacturing partner can help scale production while maintaining reliability

Your Essential Guide

This resource is a critical tool designed for:

- Engineers and R&D Teams designing EP catheters and ablation systems

- Program and Operations Managers overseeing sourcing and production

- Regulatory and Quality Professionals focused on validation and compliance

- Procurement and Sourcing Leaders evaluating potential suppliers

Whether you need low-volume, high-mix production or scalable precision, our guide outlines the requirements and solutions that matter most.

Download the Free White Paper

The Essential Guide to Selecting Your PT Electrode Tip Manufacturing Partner

Gain practical insight into how top-performing manufacturers overcome common pitfalls in electrode tip manufacturing for EP catheter components.

Read the Full White Paper

What are PT electrode tips used for?

PT (platinum-iridium) electrode tips are key components in electrophysiology (EP) catheters used to map, diagnose, and ablate cardiac arrhythmias. Their precision directly impacts signal quality and procedural outcomes.

Why is manufacturing PT electrode tips so Challenging?

Platinum-iridium’s hardness and conductivity create the need for advanced machining methods and exacting tolerances. Surface finish, plating adhesion, and internal geometries all affect electrical performance and must pass rigorous validation.

What requirements are important when manufacturing PT electrode tips?

A manufacturer should demonstrate:

- Expertise in machining precious alloys

- In-house metrology and micro-inspection

- FDA/ISO-compliant process validation

- Proven results in EP component manufacturing